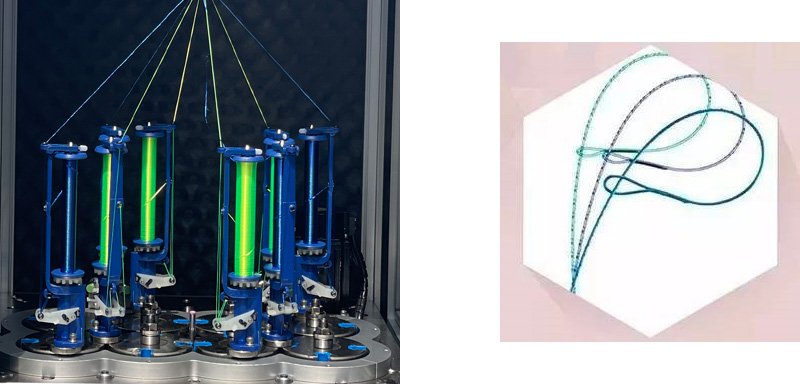

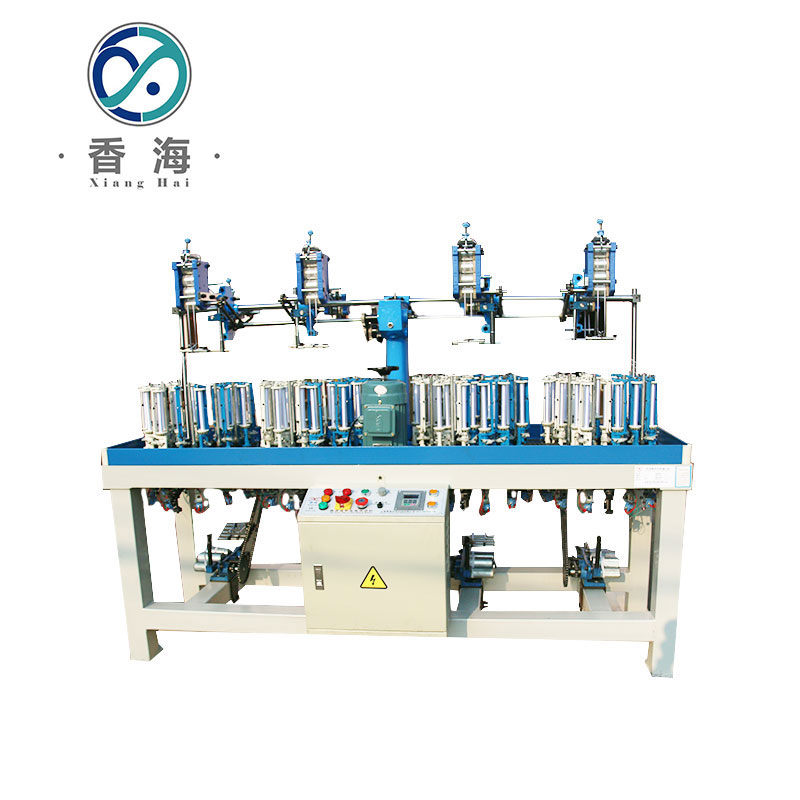

EXH Suture braiding machines are specialized in the braiding or absorbable and non-absorbable sutures with applications:Artificial ligament implantation wire weaving, implantable orthopedic bandage weaving and other functions, suitable for surgery, orthopedic, sports medicine and other applicable operations.

At present, make the closed loop knitting and lasso knitting method involves complicated post-treatment, the end of the braid with single braid to reverse, or with adhesive or heat treatment will be fixed at the end to group together, this technology will lead to the diameter of the bonded area and stiffness increase, and strength, because they are handmade. Our closed loop knitting machine is designed to overcome these shortcomings

Braiding material :Natural materials such as silk and cotton, or synthetic materials such as polyethylene (PE), polyethylene terephthalate (PET), ultra-high molecular weight polyethylene (UHMWPE), polytetrafluoroethylene (PTFE), or other biocompatible polymers.

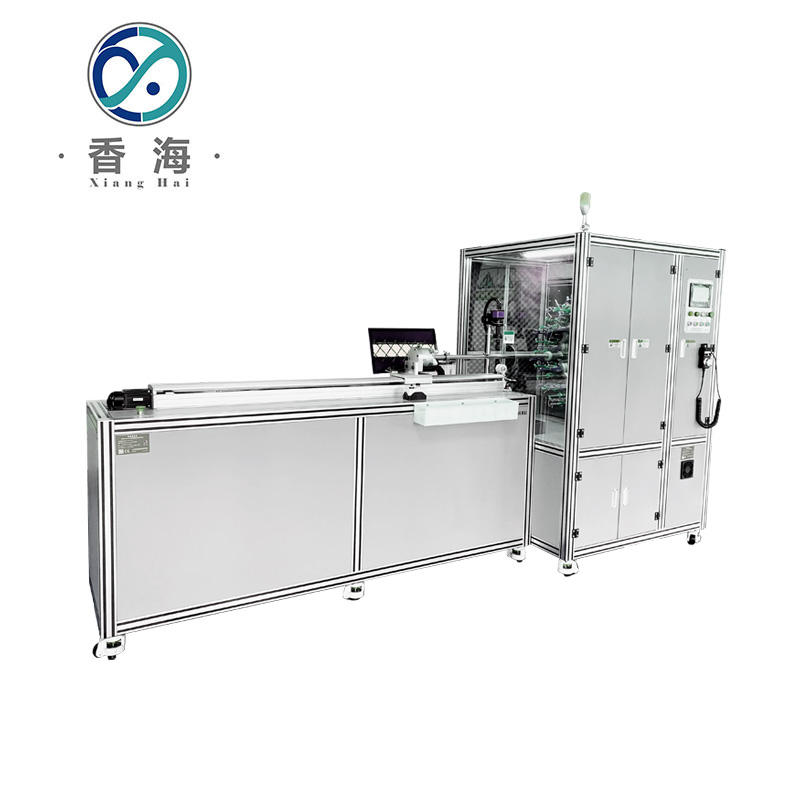

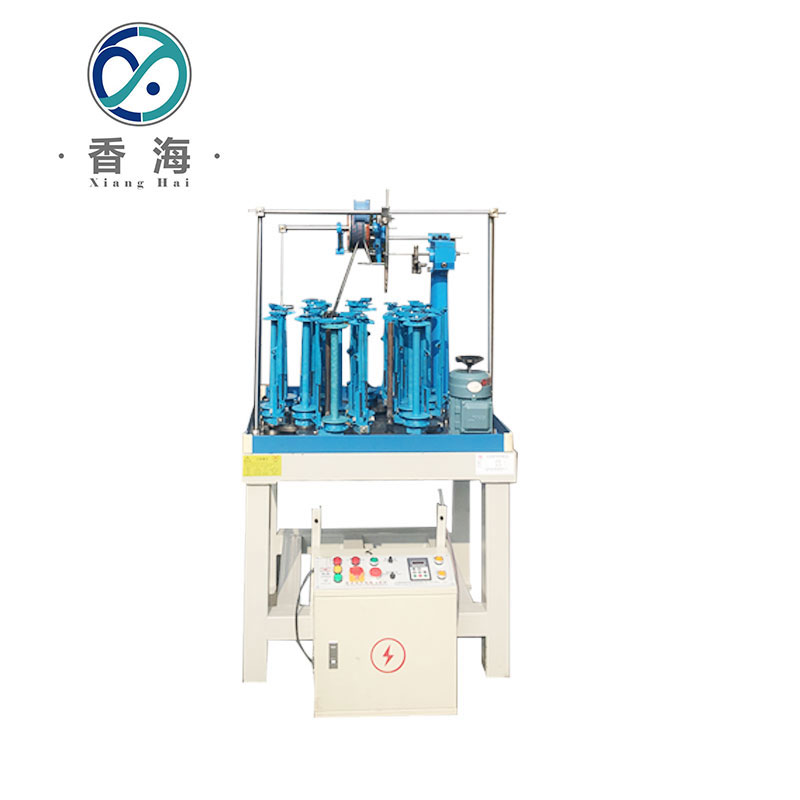

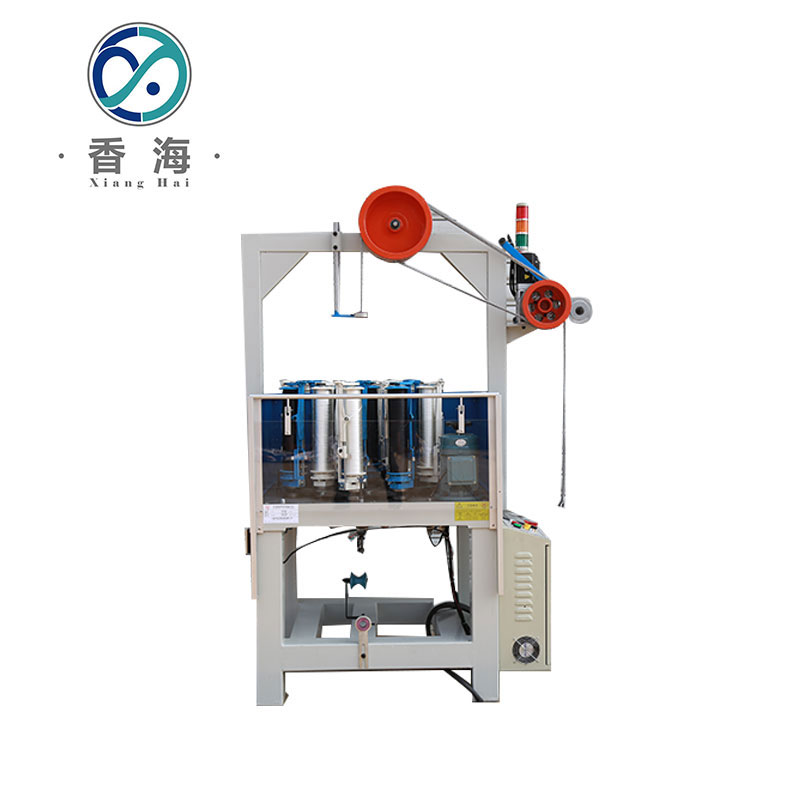

MODEL:EXH90-8-1

Main motor power:0.75kw servo motor

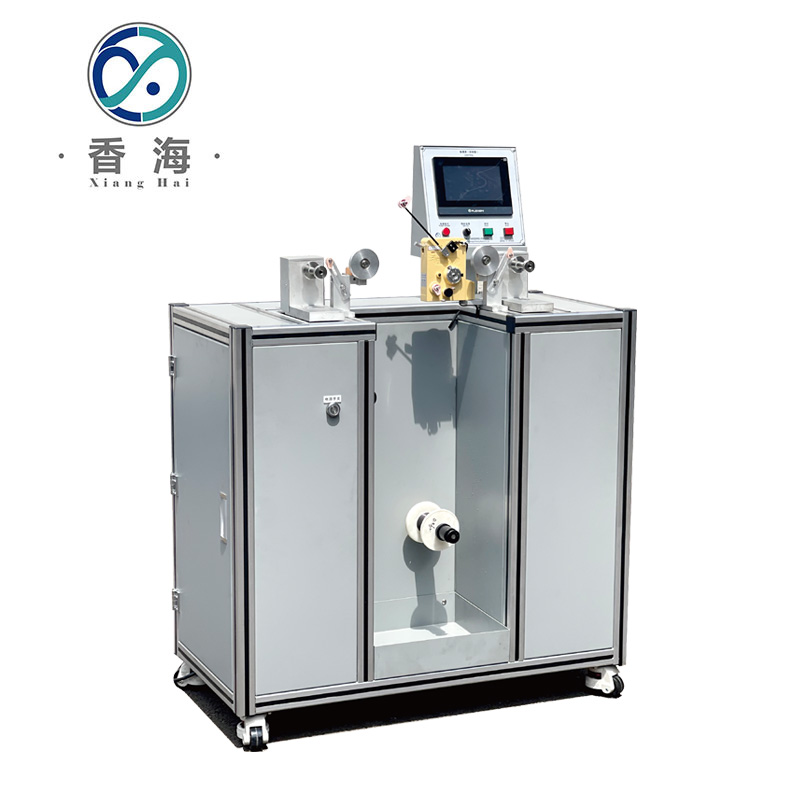

Traction wheel power:0.75kw + High precision turbine governor

Take up devices motor power:Type 86 stepping motor winding

Horngear speed:0-300 rpm/min

Carrier size:customized according to actual production

Braiding speed:0-150mm/MIN

eaving density: stepless adjustable, middle interface setting, can be graded, mutation or piecewise weaving.(equipped with automatic braiding pitch set-up system ,constant-tension payoff and take-up devcies ,which ensures the braiding precision sable and reliable) . The braiding pattern of the braided product can be realized by program control

Machine size:1700mm*671mm*601mm